The Badmotivator Barrel Story

On July 1, 2023, we lost Ben Quady, the creator of Badmotivator Barrels. Ben wasn’t just an inventor, he was a generous, thoughtful person and a respected member of the distilling community. His work and spirit continue to shape everything we do.

We're proud to carry his vision forward with what is now known as Badmotivator Legacy Barrels. Ben’s approach was always about solving real problems in the aging process, not cutting corners. His design focused on function, balance, and quality, and it worked. We’re committed to honoring that by building barrels that reflect his standards and mindset.

Ben believed in refining ideas, sharing knowledge, and doing things the right way, even if it was harder. That’s the foundation we’re standing on. While staying true to his original design, we’ll keep learning, testing, and pushing the craft, just like he did.

We’re grateful to be part of the community that Ben helped build. His legacy isn’t just in the barrels, it’s in the shared love of great spirits and the pursuit of better aging. So we raise a glass to Ben. His story lives on in every barrel we make.

Ben’s story, as told in his own words:

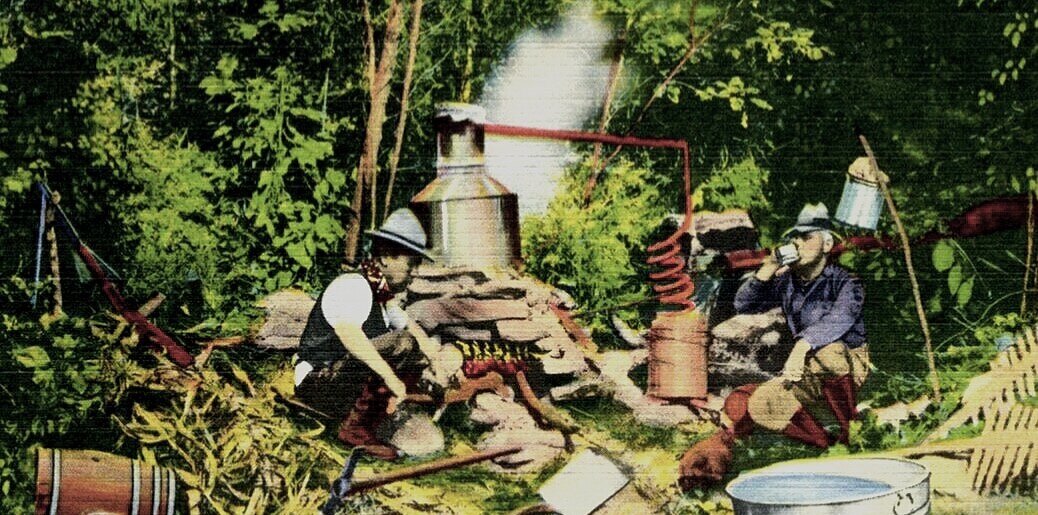

In 2015 I was looking for the best way to age and mature small amounts of rough and raw young white spirits. The techniques commonly used by home distillers, such as oak spirals, sticks, cubes, chips, and small novelty barrels, seemed to lack functionally important elements of proper long-term aging. Without access to small amounts of oxygen over a long period, extracting oak that may or may not have been weathered properly, and subjected to perhaps more oak contact than is appropriate, spirits did not mature in the way that I wanted. They gained color and oak flavor (with perhaps too much tannin) but lost none of their brash youth. We know what works though: long residence in large oak barrels.

What if you could take a cylindrical plug out of a large oak barrel, wood and spirit together, and wrap that plug in something inert like stainless steel? Wouldn’t the spirit mature properly in such a cylinder? This idea was the genesis.

I bought some oak (of uncertain species, I’m afraid), shaped it into a round barrel head, and pressed it into a stainless steel can. To my great pleasure and excitement, it became water-tight.

The next steps were refinements and corrections to some fatal flaws. First, the wood must be a suitable species, so I acquired American White Oak (Quercus alba). Second, the oak must be quartersawn, to orient the channels in the wood in such directions as to minimize loss through the natural channels (vessels/pores and medullary rays) of the wood. Third, the oak must be weathered for a long time, which reduces and modifies the tannin in the oak so that it will not destroy the flavor. I am skipping much complexity here, of course. Forgive me.

There have been other challenges related to making the barrels as reliable as possible and with as little unnecessary labor as I can. Tooling, jigs, joinery problems, etc. It’s lucky that I enjoy these problems and their solutions, because it would have been easy to give up and move on. The fun of the project is a good motivator. But I am also moved by the knowledge that the system works! The spirits mature beautifully in them! People should have these barrels!

I have gladly tutored anyone who wants to learn how they are made, and learned a great deal from other folks in the process. But of course most people can not or would not like to acquire the woodworking capability required to make their own barrels of this kind.

I feel ready to make Badmotivator Barrels in larger numbers and offer them for sale. I’m just one guy doing this in my spare time, so those numbers won’t ever be very high. I love the work and the cool people I’ve made connections with over the years.

Cheers, everyone. Thanks for reading.

-Badmotivator